Deburring

impeccably

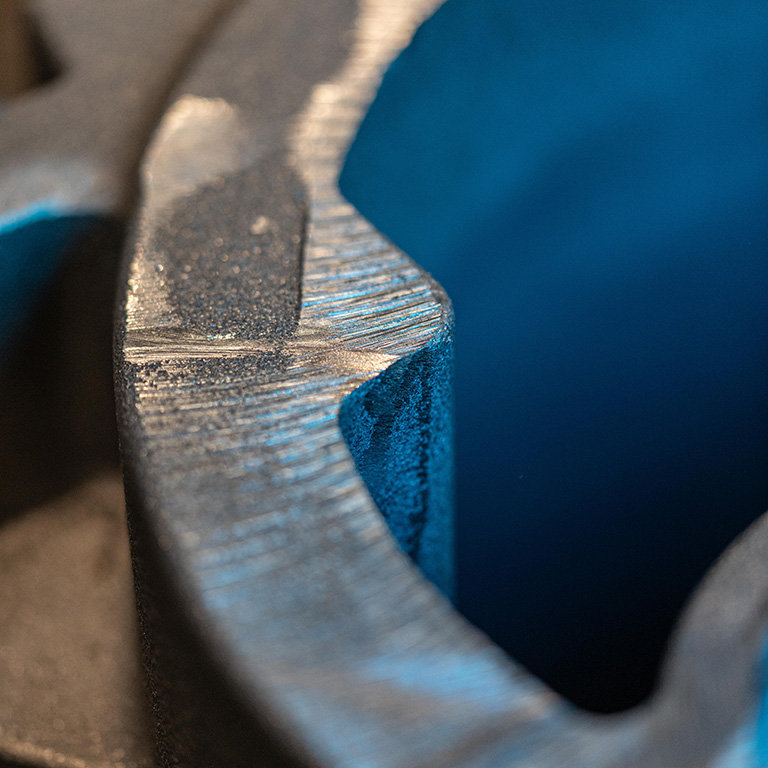

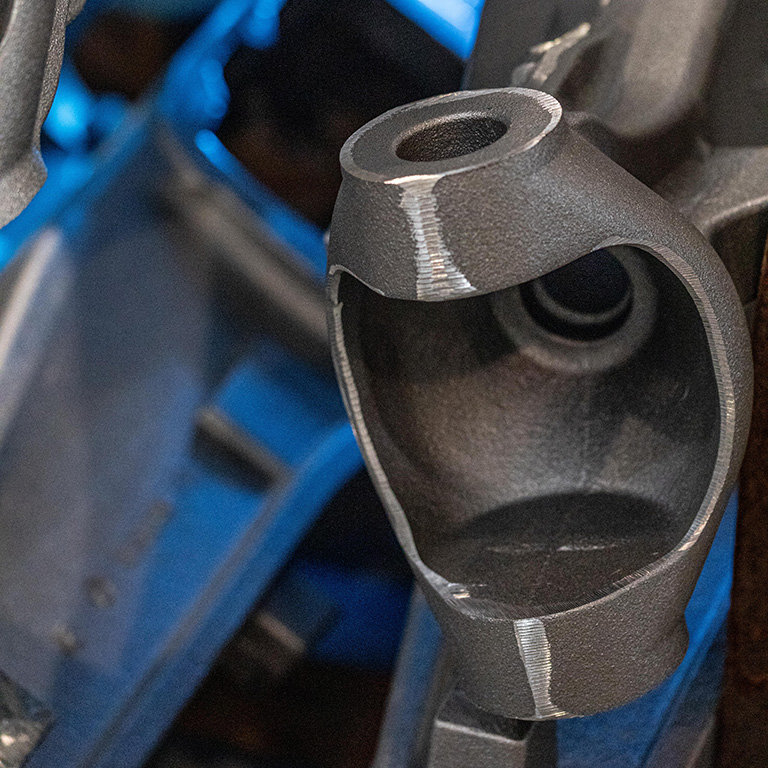

Metal deburring is the process of removing burrs, i.e. the excess material in cast products.

At our 40 soundproof workstations, dedicated to deburring cast iron castings, we work with extreme precision in order to achieve a flawless product both aesthetically and functionally.

Manual deburring

At Fercoop, the deburring of cast iron castings is performed manually by highly qualified personnel who are able to level even the most complex workpieces in hard-to-reach places.

Automated deburring

Thanks to the automatic deburring machine at Fercoop, we are able to process large quantities very quickly, thus managing large orders and reducing waste and waiting times.

Why choose Fercoop

Up to 500 kg

Deburring is performed on grey and spheroidal cast iron castings weighing from 1 kg to 500 kg.

Expertise

The fact that some of the key personnel come from the foundry sector makes it possible to maximise the competence of the personnel involved in the deburring of cast iron castings.

Customised projects

We make customised projects thanks to our team’s ability to test castings according to your specifications and their field of application.

Stop wastage

Lean production management , involving the entire organisation, allows waste to be minimised.

Rely on Fercoop!