Technology

cutting-edge

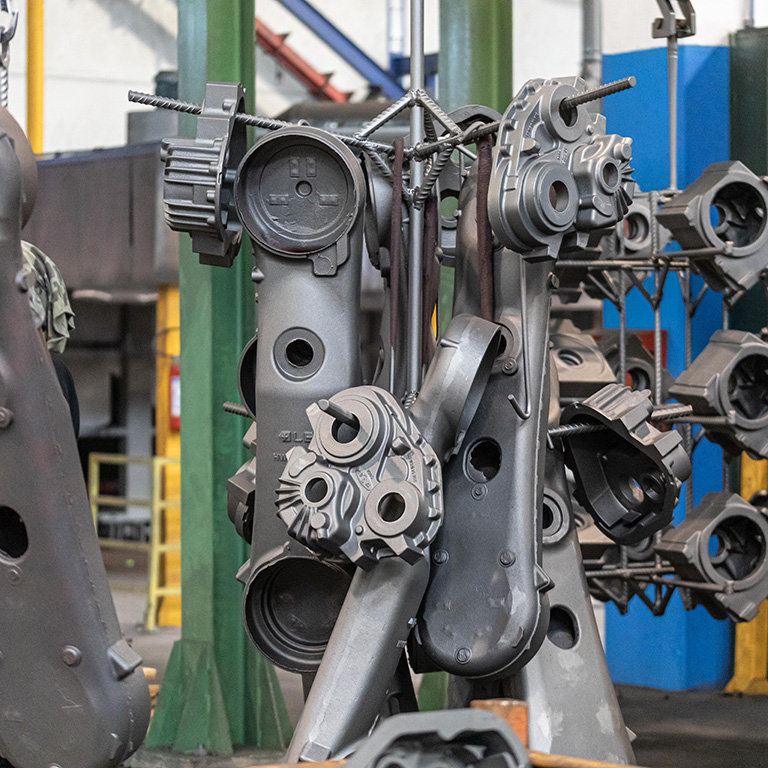

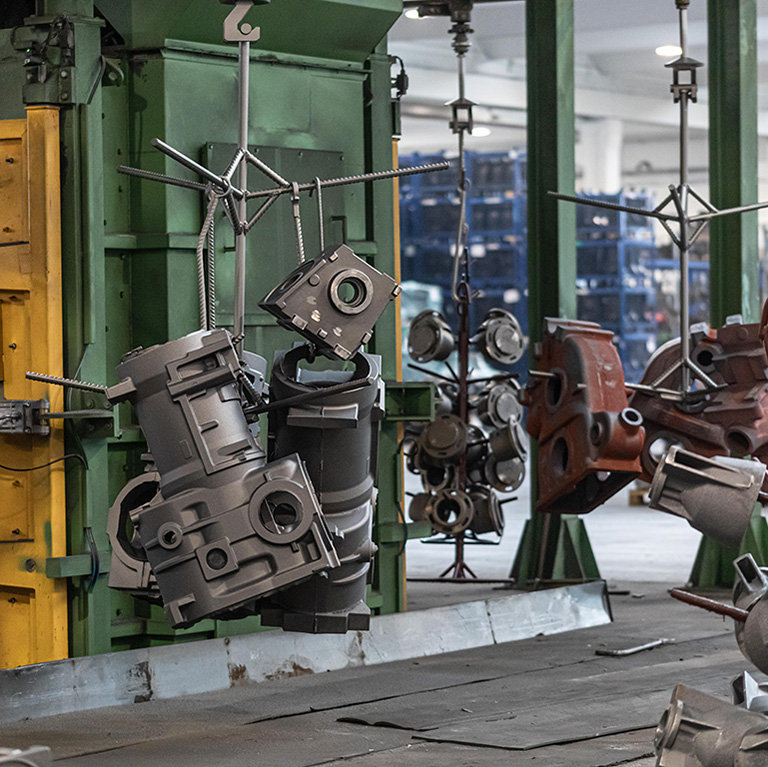

Desanding allows cast iron castings to be separated from their sand cores (the hollow section in permanent castings), removing as much of the accumulated foundry sand as possible.

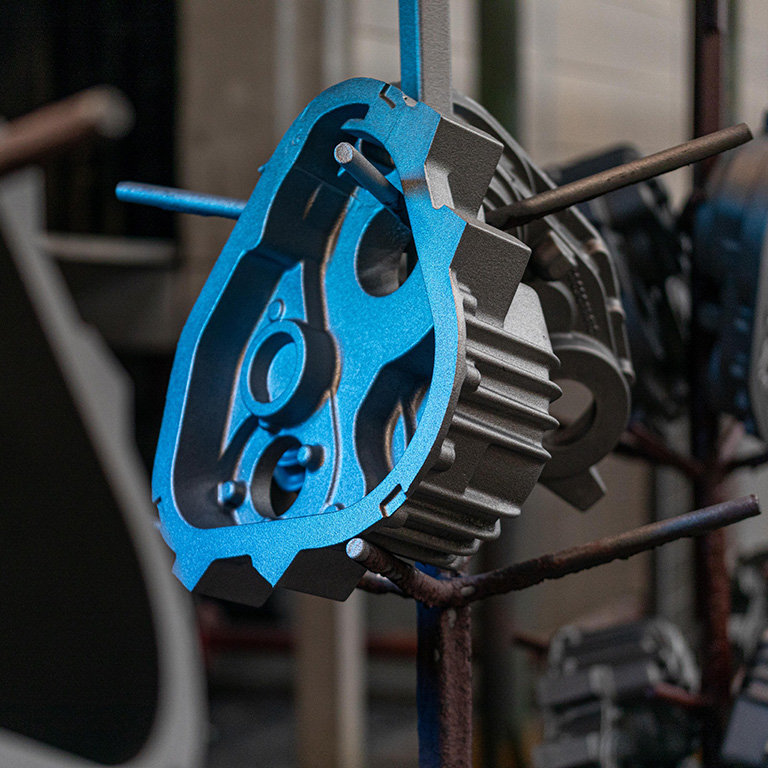

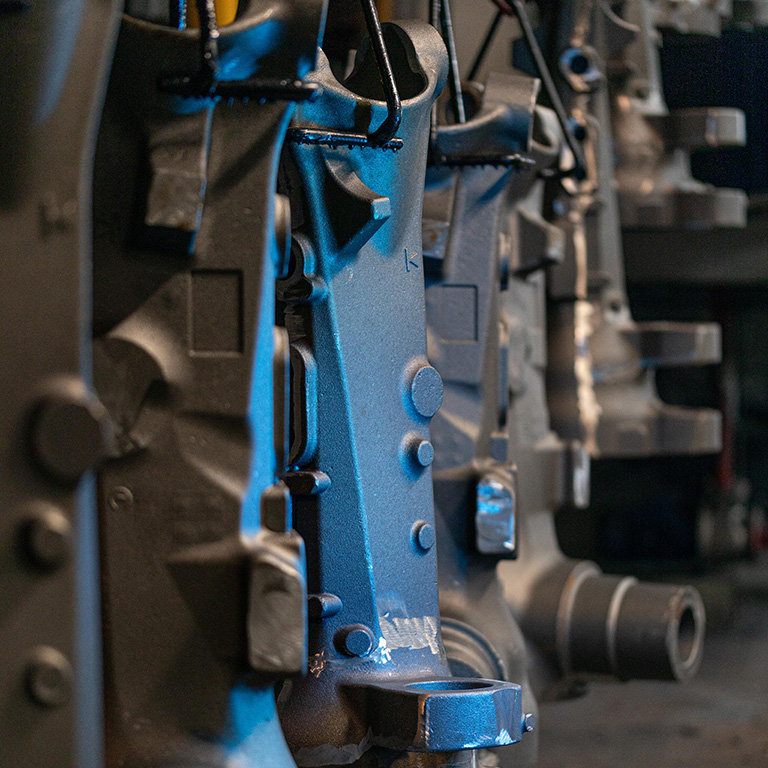

Sandblasting of cast iron castings further cleans residual sand, slag and other impurities, improving the appearance and surface quality of the finished product.

Sandblasting chambers

At Fercoop, the two sandblasting chambers are equipped with nozzles for large castings or those affected by marked and extensive sintering.

Cluster sandblaster

The cluster blasting treatment allows processing large quantities thanks to a maximum capacity per hook of 2,500 kg and a power of 30 kW of the three turbines that ensure an even finish.

Steel belt sandblaster

This sandblasting machine is characterised by bucket loading for blasting castings up to a maximum weight of about 50 kg (max. load capacity 3,000 kg).

Why choose Fercoop

High load

The technologies at our disposal allow us to carry out the desanding and sandblasting of heavy cast iron castings.

Expertise

The fact that some of the key personnel come from the foundry sector makes it possible to maximise the competence of the personnel involved in the desanding and sandblasting of cast iron castings.

Customised projects

We make customised projects thanks to our team’s ability to test castings according to your specifications and their field of application.

Stop wastage

Lean production management , involving the entire organisation, allows waste to be minimised.

Rely on Fercoop!